DIY Kantenfinder

Als CNC-Bediener muss ich bei manchen Arbeiten genau wissen, wo sich mein Werkstück befindet. Daher benötige ich in solchen Fällen die

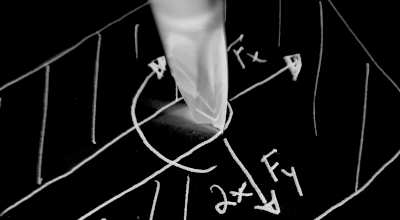

Als CNC-Bediener muss ich bei manchen Arbeiten genau wissen, wo sich mein Werkstück befindet. Daher benötige ich in solchen Fällen die X/Y-Werte einer Ecke des Werkstücks im Maschinenkoordinatensystem. Bisher habe ich dieses Problem mittels eines V-Fräsers gelöst, dessen Spitze ich manuell auf die Kante des Werkstücks verfahren und immer wieder mit Augenmaß geprüft habe, ob die Positionen übereinstimmen.

Das Problem

Obwohl diese manuelle Methode relativ schnell und unkompliziert anzuwenden ist, so ist sie für die meisten Aufträge nicht mehr genau genug. Als ich in die doppelseitige Bearbeitung eingestiegen bin wie bei diesem Werkstück, war der Versatz so groß, dass ich die ersten Teile nur noch entsorgen konnte.

Lösung

Ich habe mein Problem mit dem Hersteller meiner Fräsmaschine besprochen - in der Annahme, dass ich einen elektrischen, in die Spindel einzuspannenden Kantentaster “3D finder” empfohlen bekommen würde und nun wieder viel Geld und Arbeit in Kauf und Einrichtung eines solchen Messwerkzeugs fließen müsse. Da lag ich aber falsch. Stattdessen erhielt ich einen Tipp, wie ich einen einfachen aber genauen Kantenfinder bauen kann, der zudem praktisch nichts kostet.

Einzelteile

Roy sagte “Na ja, das Einzige, was du dafür brauchst, ist ein Kugellager. Befestige es auf einer Achse und wechsle sie in die Spindel ein wie jedes andere Werkzeug auch. Lasse die Spindel im niedrigen Drehzahlbereich laufen und bewege die Maschine langsam in Richtung Werkstückkante. Sobald der äußere Ring des Kugellagers nicht mehr mitläuft, hast du die Kante gefunden.” Alles was ich dann noch tun muss, ist, den Radius des Kugellagers auf die Maschinenposition zu addieren und ich habe die Position bestimmt.

Roy sagte “Na ja, das Einzige, was du dafür brauchst, ist ein Kugellager. Befestige es auf einer Achse und wechsle sie in die Spindel ein wie jedes andere Werkzeug auch. Lasse die Spindel im niedrigen Drehzahlbereich laufen und bewege die Maschine langsam in Richtung Werkstückkante. Sobald der äußere Ring des Kugellagers nicht mehr mitläuft, hast du die Kante gefunden.” Alles was ich dann noch tun muss, ist, den Radius des Kugellagers auf die Maschinenposition zu addieren und ich habe die Position bestimmt.

Aufbau

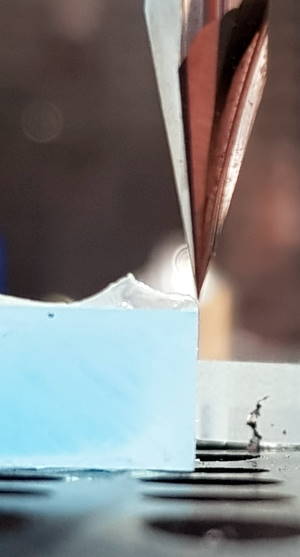

Ich fand die Idee genial. Da ich leider kein gut sortiertes Metallfachgeschäft in der Nähe habe, durchwühlte ich den Haushalt nach einem Kugellager. Voilà, meine Kinder haben einen Fidget Spinner, den sie eine Weile nicht mehr benutzt haben. Also habe ich ihn… stibitzt. Er enthält ein Kugellager mit 22mm Durchmesser für eine 8mm Welle.

Hierfür bot sich der Schaft eines stumpfen 8mm Bohrers an. Also schnitt ich ihn in der Mitte durch, setzte den Schaft in das Kugellager ein und befestigte ihn mit einem Tropfen Kleber - Fertig!

Hierfür bot sich der Schaft eines stumpfen 8mm Bohrers an. Also schnitt ich ihn in der Mitte durch, setzte den Schaft in das Kugellager ein und befestigte ihn mit einem Tropfen Kleber - Fertig!

Update: Kurz nach Veröffentlichung dieses Artikels schrieb ein Leser, dass alte Inline Skates oder Roller auch hervorragende Spender für Kugellager im Haushalt seien.

Kanten finden

- Wechseln Sie den selbstgebauten Kantenfinder in die Spindel ein und verfahren sie in die Nähe des Werkstücks

- Schalten Sie die Spindel bei niedriger Drehzahl ein, z.B.

S500....S3000 - Optional: Für eine einfachere Positionsbestimmung wechseln Sie in das Maschinenkoordinatensystem

- Lassen Sie die Maschine langsam in Richtung des Werkstücks fahren, z.B. mit dem Kommando

G01 X<endpunktImWerkstück> F1 - Drücken Sie auf

Stop/Pause, sobald das Lager sich nicht mehr mitdreht - Notieren Sie sich die Maschinenkoordinaten bzw. verschieben das Arbeitskoordinatensystem der angetasteten Achse

G92auf diesen Punkt - Wiederholen Sie ab Schritt 2 für die nächste Achse

Einfacher Kantenfinder im Einsatz.