My CNC vibrates

Background

Lately, I have been pushing my machine closer to its limits. I’m now often formatting plywood full-slot with one pass meaning the machine has to take a Z+ of 12mm at F2700mm/min on a 6mm 2-flute rougher bit at S=24000rpm. I’m using climb milling for my projects in wood.

Now the machine sometimes starts vibrating.

You might say “just reduce machine load by setting a more shallow depth of cut”, “slow down your feed rate and spindle RPM”, or “Don’t take a rougher, that’s always inducing more vibration” - and I might follow of your advice at some point, but first I want to understand what’s exactly going wrong here and whether I can fix this issue without sacrificing machine time or cutter life.

Problem description

Machine vibration doesn’t only happen while formatting but also when I cut pockets, but it seems like only at certain positions during the cut. It feels like the whole machine is shaking just a little, but the sound of it makes me doubt that everything is alright. I captured two samples for your reference below.

Vibrations manifest at certain positions of the machine while pocketing (80% clearing feed)

Vibrations during formatting

Analysis

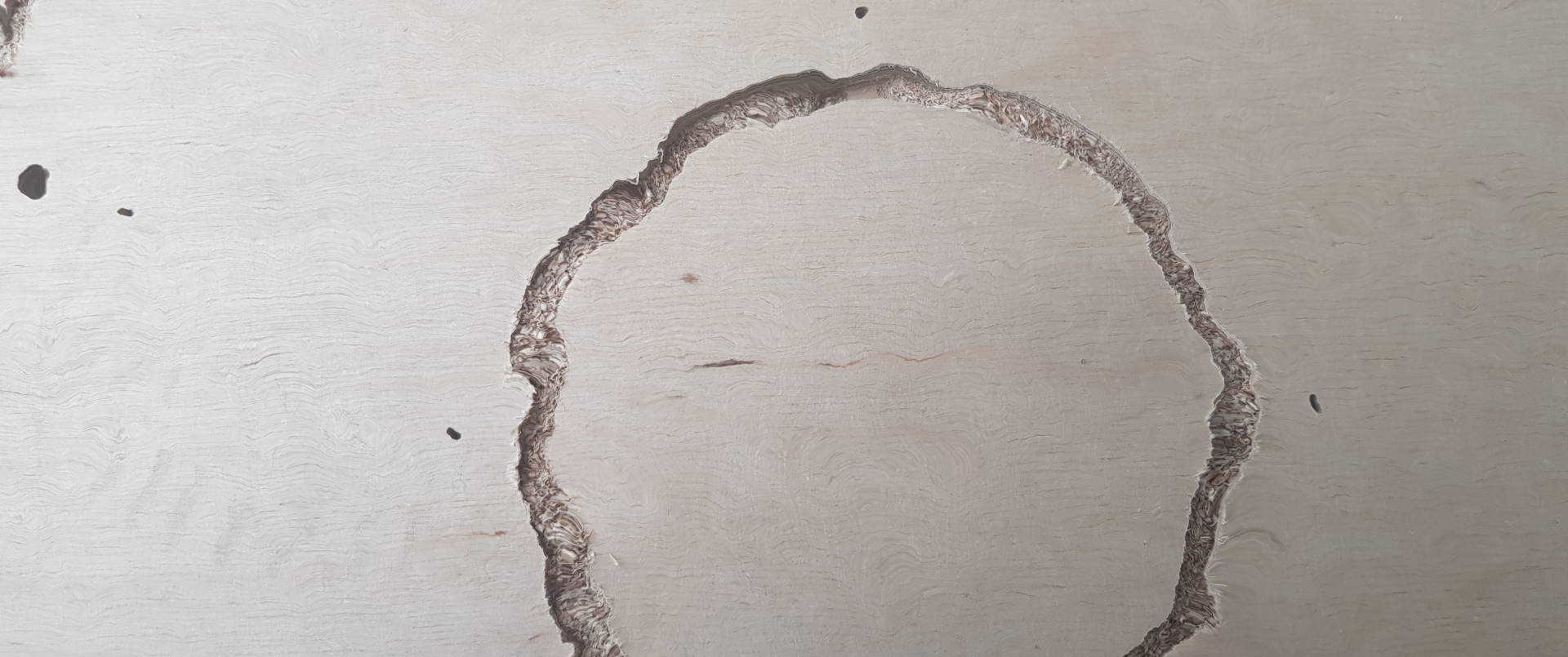

Cutting results are looking good to me still…

I retried with somewhat different settings: Reduced Z+ of only 6mm but increased feed of 3600mm/min with the same bit I used before - vibrations gone.

After contacting the machine manufacturer (refer to this thread in German), the most likely reason for the vibration is the router and its clamp that mounts to the Z-axis.

The router has less high-end bearings than heavy-duty spindles so they are subject to play. In addition, the 42mm standard clamp is attached to the Z-axis with two M8 fasteners while the router is clamped with only one fastener around its “neck”.

The router has less high-end bearings than heavy-duty spindles so they are subject to play. In addition, the 42mm standard clamp is attached to the Z-axis with two M8 fasteners while the router is clamped with only one fastener around its “neck”.

HF-spindles are most often flush-fastened directly to the Z-axis so the contact surface is incomparably higher, leaving little or no room for vibration.

Result

I have three options now:

- Continue with high depth milling and tolerate vibrations and additional noise

- Change to more shallow passes which solves vibration issues but adds machining time

- Upgrade the spindle which adds considerable cost to my setup

- Upgrade the machine bed to stiffen the machine frame

Update September 2023

I upgraded both machine bed and spindle. The vibrations are still there. Frustrating.

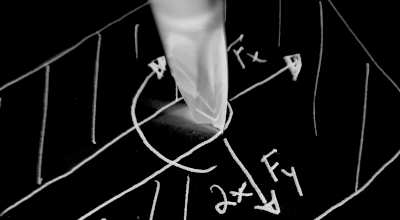

When I look at it again, I see vibrations emerge when moving both X and Y axis. When I move Y only, vibrations are gone. In case I move X, though, there’s a small amount of vibrations.

Working assumption now is that the root cause lies in axis stability. I have quite a wide machine with just one ball screw in its center, and one instead of two linear guides on the Z-axis. I’ll analyze at a later point in time what exactly I can do to get rid of the vibrations.