CNC: Überlastung Fräsmotor

Was ich eigentlich wollte

Ich hatte eine Anfrage zum Schneiden und Gravieren von Hochdrucklaminaten. Dabei handelt es sich um eine Lasagne aus gepresstem Papier und Phenolharz, überzogen mit einer dünnen Schicht (farbigen) Melaminharzes. HPL ist so widerstandsfähig, dass es für Fassadenbeplankungen verwendet wird. Es ist spülmaschinenfest und einige Varianten können auf bis zu 200°C erhitzt werden, ohne Schaden zu nehmen. HPL findet man als Platten auf Spielplätzen, Gartentischen, als Paneele in der Straßenbahn usw. Also dachte ich mir: “Cooles Zeug, lass auf geht`s!”

Schnittdaten in Hochdrucklaminaten (HPL, “Resopal”)

Ich habe die von einigen Websites empfohlenen Schnittdaten mit Werten für “Hartholz” verwendet.

2-Schneiden-Holz-Hartmetall-Schaftfräser, Schnittgeschwindigkeit

Ich habe die von einigen Websites empfohlenen Schnittdaten mit Werten für “Hartholz” verwendet.

2-Schneiden-Holz-Hartmetall-Schaftfräser, Schnittgeschwindigkeit 450m/min, 6mm, Z+6,5mm, S24000rpm, F3500mm/min, Vollnut, Gleichlauffräsen.

Schnittergebnisse

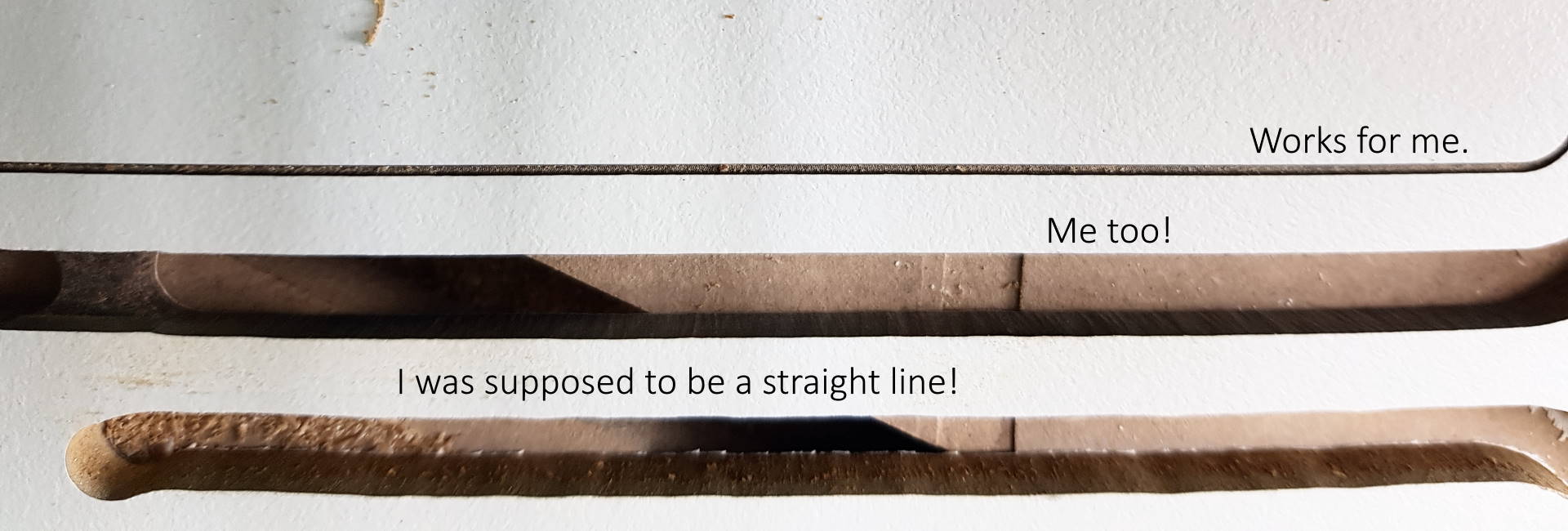

Und ich war erschrocken, wie der Schnitt aussah, als ich fertig war. Hier sind die Symptome:

- Während des Schneidens fiel die Spindeldrehzahl wiederholt ab, stieg aber schnell wieder auf die gewünschte Drehzahl an.

- hohe Spanlast am Fräser, große Späne, sah alles gut aus

- der Fräser folgte keiner geraden Linie: schien dem Material irgendwie ausweichen zu wollen.

- bei der Herstellung von Anbindungen, um das Werkstück an Ort und Stelle zu halten, entspannt sich der Fräser ein wenig seitwärts, obwohl er das nicht sollte

Suche nach dem Übeltäter

Zuerst habe ich die Spindel überprüft. Keine Überhitzung, immer noch fest an der Portalfräse eingespannt, kein Lagerspiel, Schaftfräser sicher befestigt. Dann dachte ich: “Vielleicht stimmt etwas mit dem Portal nicht? Kann ich es merklich verwinden?” Nein, das konnte ich nicht. Dann sah ich mir den Schaftfräser an.

Es sah überhaupt nicht gut aus. Die Schnittkanten waren an den Stellen, an denen sie das Material berührt hatten, praktisch weg. Seltsam. Es war nagelneu, als ich den Auftrag begann, und es lief nicht einmal 20 Minuten lang.

Es sah überhaupt nicht gut aus. Die Schnittkanten waren an den Stellen, an denen sie das Material berührt hatten, praktisch weg. Seltsam. Es war nagelneu, als ich den Auftrag begann, und es lief nicht einmal 20 Minuten lang.

Analyseergebnisse

- Ich habe viel zu aggressive Schnittdaten verwendet.

- Dadurch wurde der Motor der Oberfräse weit über seine Möglichkeiten hinaus betrieben.

- Dies führte zu einem plötzlichen Abfall der Motordrehzahl.

- Dies wiederum führte zu einer erhöhten Spanbelastung meines Schaftfräsers

- Da die Lager und die Befestigung der Oberfräse am Portal “weich” sind, versuchte der Fräser, seiner Fräsbahn auszuweichen

- Dies hat mich wahrscheinlich vor einem zerbrochenen Schaftfräser bewahrt.

Verbesserungen

Researching HPL parameters (again)

Ich habe nochmal online recherchiert. HPL ist unglaublich hard und steif. Hier mal ein paar Werte zum Vergleich (Brinellhärte):

Desweiteren fand ich einige Empfehlungen zur spanabhebenden Verarbeitung von HPL, z.B.: “Vollhartmetallfräser sollten eine Schnittgeschwindigkeit von bis zu 150m/min” und “Diamantbeschichtungen aufweisen oder als Einschneider zur Bearbeitung von Aluminium ausgeführt sein”.

Zwischenlösung

Um die Dinge zu korrigieren, habe ich alle Ausschnitte mit den Schlicht-Einstellungen in CAM erneut durchgeführt. Mit einem neuen Schaftfräser und weniger aggressiven Vorschubgeschwindigkeiten von

Um die Dinge zu korrigieren, habe ich alle Ausschnitte mit den Schlicht-Einstellungen in CAM erneut durchgeführt. Mit einem neuen Schaftfräser und weniger aggressiven Vorschubgeschwindigkeiten von F2500mm/min und einer aktualisierten Tiefe pro Durchgang von Z+1,5mm.

Das Ergebnis sieht jetzt viel besser aus.

Optimierung der Schnittdaten

Dann berechnen wir schnell mal neue Schnittdaten aufgrund der oben gewonnenen Erkenntnisse. Ich wähle einen 4mm Einschneider (z=1) mit Beschichtung zur besseren Wärmeabfuhr für Aluminium und lege die oben genannte Schnittgeschwindigkeit von vc=150m/min für HPL zugrunde. Weiterhin wähle ich einen Zahnvorschub von fTooth = 0,025mm, ähnlich wie beim Fräsen von Stahl.

Zieldrehzahl: \(n=\frac{v_c}{\pi d}=\frac{150000\frac{mm}{min}}{\pi \cdot 4mm}=12000\frac{1}{min}\)

Zielvorschub: \(F=n \cdot f_{Tooth} \cdot z = 12000\frac{1}{min} \cdot 0,025mm \cdot min \cdot 1= 300\frac{mm}{min}\)

Ich habe einen 4 mm-Schaftfräser gewählt, weil das Drehmoment meines Oberfräsenmotors überproportional abnimmt, wenn ich die Drehzahl reduziere. Bei größeren Schaftfräsern würde dieser Effekt wahrscheinlich zu einer unzureichenden Schnittleistung führen. Wenn Sie eine Spindel mit einer Asynchronmaschine haben, ist Ihre Drehmomentkurve im unteren Drehzahlbereich flach (und bei Vektorsteuerung kann es sogar deutlich über dem Nennmoment des Motors liegen), so dass dies kein Problem darstellen sollte.

Der Vorschub kommt mir so langsam vor - ich hoffe, dass sich das Material dadurch nicht zu stark erhitzt, dass es delaminiert (laut Wikipedia schmilzt es nicht…)

Zur Information: Hier ist der zugehörige Thread in dem Forum, das ich regelmäßig besuche.

Weitere Tests

Ich habe einige Teile mit oben angesprochenem Fräser und Einstellungen gefertigt. Um die Fertigungszeiten etwas im Zaum zu halten, habe ich die Werte leicht angepasst:

Ich habe einige Teile mit oben angesprochenem Fräser und Einstellungen gefertigt. Um die Fertigungszeiten etwas im Zaum zu halten, habe ich die Werte leicht angepasst: ftooth = 0.04mm und vc = 130m/min. Für den 4mm Fräser ergibt sich

S = 10300U/minF = 410mm/minZ+ = 3mmvc = 1%

Dieser Schaftfräser lebte etwa 1 Stunde lang. Nicht viel. Das Schneiden mit einem solchen Fräser könnte nie wirtschaftlich werden. Das HPL, das ich verwende, hat zwei Materialeigenschaften, die Hartmetallfräser schnell zerstören: Erstens ist es abrasiv, so dass die dünne Schneide des Fräsers abgetragen und zerstört wird. Meins ist ganz besonders abrasiv, da es einen unheimlich hohen Faseranteil besitzt. Zweitens leiten die Späne die entstehende Wärme nicht gut von der Schneide ab, so dass ihre Schärfe noch schneller nachlässt. Hitze scheint das Kryptonit für Hartmetallfräser zu sein.

Endgültige Lösung

Eine wirtschaftlichere Lösung mit 40-facher (Herstellerangabe) Lebensdauer wäre ein Hartmetallfräser mit Diamantschneiden (z. B. wie dieser hier). Der Nachteil ist, dass sie fast zehnmal so teuer sind. Wenn ich dieses Material in Zukunft öfter schneiden muss, kaufe ich vielleicht einen und teile meine Erfahrungen - in der Zwischenzeit lasse ich die Fräser lieber schärfen, um Geld zu sparen.